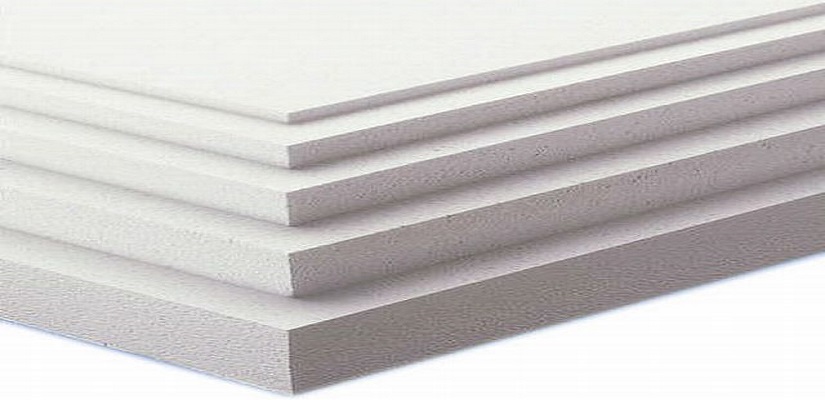

Reasons for Using EPS Thermocol in the Construction Industry

The best features of EPS Thermocol are Reliability, Versatility, Recyclability, and Moisture Resistance. Below is the main Physical, Mechanical, Thermal, and Economic factors that make Expanded Polystyrene (EPS) Thermocol a durable material in the construction industry.

- Reusability potential

- Time-saving

- Hot weather resistance

- Fire resistant

- Cold weather resistance

- Strength and stability

- Resistance to the impact of sound

- Water-resistant

Thermal resistance

EPS Thermocol offers higher thermal resistance than concrete. Due to its low thermal conductivity, EPS Thermocol consumes less energy. Therefore, the material is suitable for regulating extreme temperatures inside the building. Its closed structure, filled with air, prevents the passage of cold or heat. EPS Thermocol has high thermal insulation and low thermal conductivity.

Low construction cost

The weight of an embedded EPS Thermocol structure is 35% less than a traditional concrete structure. This EPS Thermocol feature encourages builders to use pre-assembled structural elements to reduce the total cost of building construction.

Load resistance

After compression tests, the finished single sheet showed promising results for the researchers. The panel showed high load resistance. It has been proven that a single panel can withstand a load of 1530 kN/m. The monolithic seams of the building ensure a high level of structural strength.

Light weight

The density of the EPS Thermocol blocks varies from 10 to 45 kg/m³. The low density of the material results in lightweight, which ensures ease of use and transport. EPS Thermocol ensures increased safety of construction works due to its low weight.

Mechanical stability

Its excellent mechanical stability makes it very suitable for insulation work on load-bearing roofs, road construction, and paving floors.

Water resistance

As a rule, the thermal and mechanical properties of the material deteriorate with humidity, dampness, and moisture. EPS Thermocol has a low water absorption property. We cannot expect any change in these properties with the use of EPS Thermocol for long periods. This makes EPS Thermocol suitable for construction in swampy conditions.

Chemical resistance

Compatibility with other materials makes EPS Thermocol an ideal material for construction. This was possible due to the chemical resistance of EPS Thermocol. It is compatible with cement, plaster, fresh, salt water, and additives.

Versatility

The versatility of EPS Thermocol lies in its flexibility to cut the required shapes and sizes. EPS Thermocol is distinguished from other building materials by its ability to fit into any building object. It cannot be affected by any fungus or parasite as it has no nutritional value.

Conclusion

Expanded Polystyrene (EPS) Thermocol as a construction material offers technical, environmental, social, and commercial advantages. Knowing these unique features, no one will refuse to use EPS Thermocol for their construction needs. Finally, the aging resistance of EPS Thermocol sheet is an ideal material for preserving all properties throughout the life of the building.

EPACK POLYMERS is a well-known and promising manufacturer & supplier of Expanded Polystyrene (EPS) Thermocol in India. Contact us for any project you want to build. Our experts are always ready to help you clear your doubts about the use of EPS Thermocol in the construction industry.